Top Dressing Fertilizer For Maize: Why Timing is Key

The key word is timing; Top dressing fertilizer works best when the timing is best (the right crop groth stage at the recommended rate.) This explains why application of urea is dependant on understanding of growth stages.

The key word is timing; Top dressing fertilizer works best when the timing is best (the right crop groth stage at the recommended rate.) This explains why application of urea is dependant on understanding of growth stages.

Top Dressing Fertilizer For Maize Nitrogen applied at the 3-4 leaf stage with a broadcaster leaves nitrogen vulnerable to leaching when the crop does not require it.

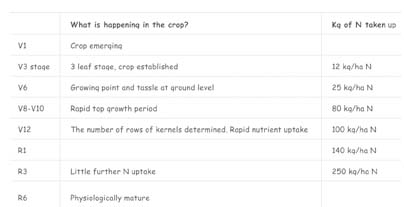

Nitrogen and other nutrients are not taken up at a constant rate through the crop life.

A summary of the important growth stages and the amount of nitrogen in particular that the crop takes up at each stage.

Leaf Tests are a Crucial Guide

Leaf Tests (or leaf nutrient analysis) are an important tool to take a snapshot of what is happening inside the plant. They will also highlight other nutrients and guide on;

- Whether there was enough application of phosphate in the seedbed and whether there’s need to change.

- If Boron is at levels that might limit kernel numbers

- How much and how soon to apply nitrogen top dressing

- Comparing any trials in the field – has seedbed Boron or Zinc actually gotten into the plant and is it needed?

Leaf Nutrient Analysis

After deciding how much top dressing fertilizer for maize to apply, consider splitting the application.

- This reduces the risk of leaching;

- Improves application timeliness;

- As a general rule, the little-and-often approach means N is more efficiently taken up by the plant.

Which Fertilizer is Best for Top Dressing Maize?

In recent years there has been a trend among maize growers to apply Calcium Ammonium Nitrate (CAN) fertilizer to their crops in preference to Urea. The lower volatilization risk in dry soils and the perceived neutral effect on soil acidity has encouraged the trend, along with the subsidized price through the National Cereals Produce Board (NCPB).

But how accurate are these claims, and what is the best value approach for your crop? Calcium Ammonium Nitrate (CAN) contains 28% nitrogen typically and is rapidly and efficiently taken up by plants. The Nitrogen content is far lower than Urea however which contains 46% nitrogen, so the actual cost per Kg of Nitrogen is more expensive.

Cost analysis have shown that the Nitrogen in Calcium Ammonium Nitrate (CAN) costs 65% more than Urea because it is less concentrated. So even if some N is lost after applying Urea, it is still far less expensive than CAN. Applied in the right conditions to moist soils, losses are very small. In most soils the acidifying effect of Urea is minimal, and the Calcium in CAN is not in a form that is particularly available.

Maize Fertilizer Requirements per Acre  Maize can easily achieve 9 tons/ ha (40 bags per acre) with the right agronomy and adequate moisture, but it does require adequate nutrition to achieve this.

Maize can easily achieve 9 tons/ ha (40 bags per acre) with the right agronomy and adequate moisture, but it does require adequate nutrition to achieve this.

The amount of fertilizer required is best calculated by multiplying the target yield in tons per hectare, by 20-25 Kg. For a 30 bag per acre crop this is 160 Kg of nitrogen.

Timing is final part of getting fertilizer right; DAP or a compound fertiliser at planting forms a good base for crop emergence, with the balance applied as urea as a topdressing. Soil Mineral Nitrogen testing can help too, by accounting for residual nitrogen in the soil profile.

And finally, top yields require accurate application. This can be discussed in detail with your agronomy contact for independent agronomic advice.

Maximizing the Performance of Urea Top Dressing

Urea remains the least expensive form of Nitrogen as compared to CAN (depends on the volatility of fertilizer bag prices). But what are the likely volatilization losses, and is it possible to go some way predicting this?

More recent work suggests that while urease inhibitors and controlled release fertilisers do work effectively, the overriding views of independent researchers show that losses from untreated urea are rarely large enough to make a coating / inhibitor worthwhile.

Looking at some trials done elsewhere, the consensus is that a maximum of 20% of applied N is lost from Urea, and usually far less (link at the bottom). That said, in the real world there are often practical reasons for using them as we cannot always spread large acreages in perfect conditions, and if the weather forecast is wrong having some protection on the urea to reduce losses it very desirable.

Factors Affecting Volatilization Losses In Top Dressing Fertilizer

- High soil temperatures

- Low rainfall

- Moist soil surface that breaks down prills, then dries out

- Lots of surface residue

- High soil pH

- Organic Matter (correlation with Urease enzyme activity so faster conversion to ammonia)

- Windy conditions

- High lime content on the soil surface (chalk soils)

How To Apply Top Dressing Fertilizer For Maize

|

Broadcaster / spinner Pros

Con

Side dresser with drop pipe Pros

Cons

|

Side dresser injected Pros

Cons • Slow work rate • Soil disturbance, especially in notill situations. Also disrupts the herbicide layer Foliar urea Pros

Cons

Whatever you do, always try to apply a double and a nil (half rate) rate strip to understand the response that the crop is giving you. |

Choosing a Fertilizer Spreader For Maize Top Dressing

Choosing the correct fertilizer spreader can open up possibilities for the material you spread, and importantly can help you get the job done quickly and efficiently when the application window is right…

Spreading width

This will normally depend on tramline width, but a high quality materials will happily spread to over 40 metres. Lower quality Ammonium Sulphate and Urea on the other hand is a much less expensive way of buying sulphur, but will require two passes and the AS will struggle to spread even 12 metres.

Hopper size

An important consideration for larger farms, as the option of buying in bulk 1 ton bags will soon become a reality.

Auto section shut-off

The smaller the fields and the more short work you have, the more this will pay you back in reducing overlaps and also minimizing lodging on the headlands. Everyone talks about the pros and cons of Urea vs Calcium Ammonium Nitrate (CAN) fertilizers and volatilization etc. In reality many farmers can improve their efficiency far more by spreading their fertilizer correctly. Accurate section control also avoids under-application on the headlands; the largest part of the field.

Weigh cell

Weigh cell

On-the-move calibration allows lower quality materials to be used, because even when the density changes the spreader adjusts and still applies the same amount. The real top-end machines have torque-sensing on the disc shafts that detect the amount of fertilizer on the disc and adjusts the position of the fertilizer falling onto the disc to maintain the spread pattern.

Forced feed

Bredal have a very good forced metering system using a small belt to deliver the fertilizer right onto the discs. Great for slightly variable quality fertilizer where the odd lump or damp bag needs some help to get through the machine evenly.

Isobus

Plug-and-go into the tractor controls is a must for section control and allows variable rate application plans to be fed into the machine – something that the very best performers are already doing.

Fill height

Often forgotten, but making a machine easy to fill can save hours when there is a short window to apply the fertiliser and you are re-filling every 20 minutes. High fill spreaders are great with tractor loaders and handlers, but it is amazing how often you see cracks in the frame where operators drop them right onto the ground to get the hopper low enough.

Maximum spread height

An important consideration for topdressing tall crops such as Sunflowers!

Hydraulic drive

Easy to couple up to the tractor with no PTO, and more precise disc speed and spread pattern over hilly terrain.